AeroFEM Reverse Engineering

AeroFEM supports your project with state-of-the-art reverse engineering tools.

Using innovative 3D scan technology, we can scan individual parts or entire assemblies on site. With our software tools and the scan data, we are able to analyse, prepare and modify the required geometry and to create all the required production data including drawings.

Important use cases of reverse engineering are:

- structural repairs

- structural review following accidents

- analysis of surface deviations

- retrofits

- development and documentation of modifications

- analysis of wear and creep

The biggest advantages of 3D measurement compared to conventional measurement are:

- greater accuracy

- higher completeness

- greater speed

- full reproducibility

- easier documentation

We would be happy to support you with our reverse engineering know-how and can provide a wide range of possible solutions for your projects. If you have any questions or project ideas, we are at your disposal.

Contact us for more information

Stefan Rohrer

BSc Hochschule Luzern/FHZ in Mechanical Engineering

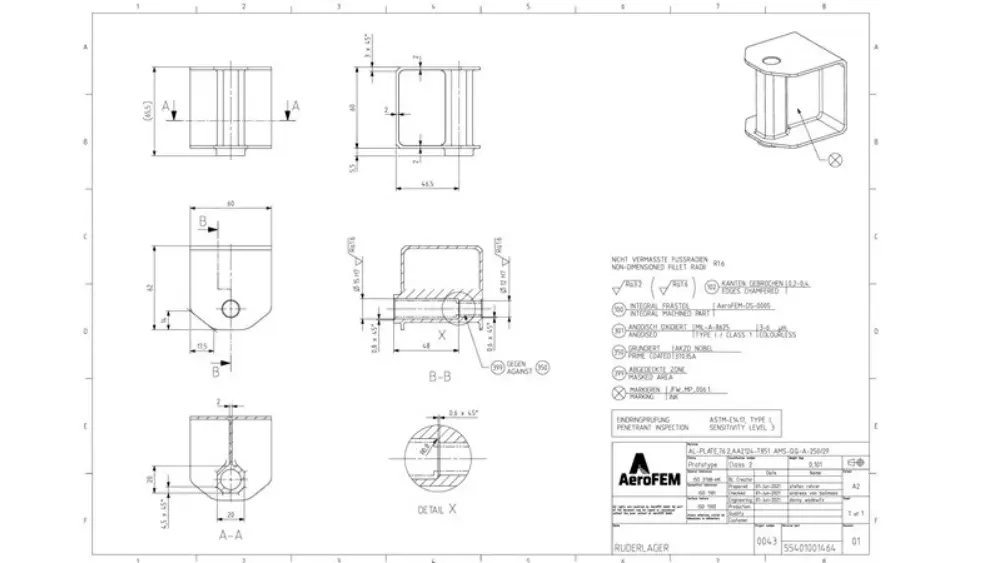

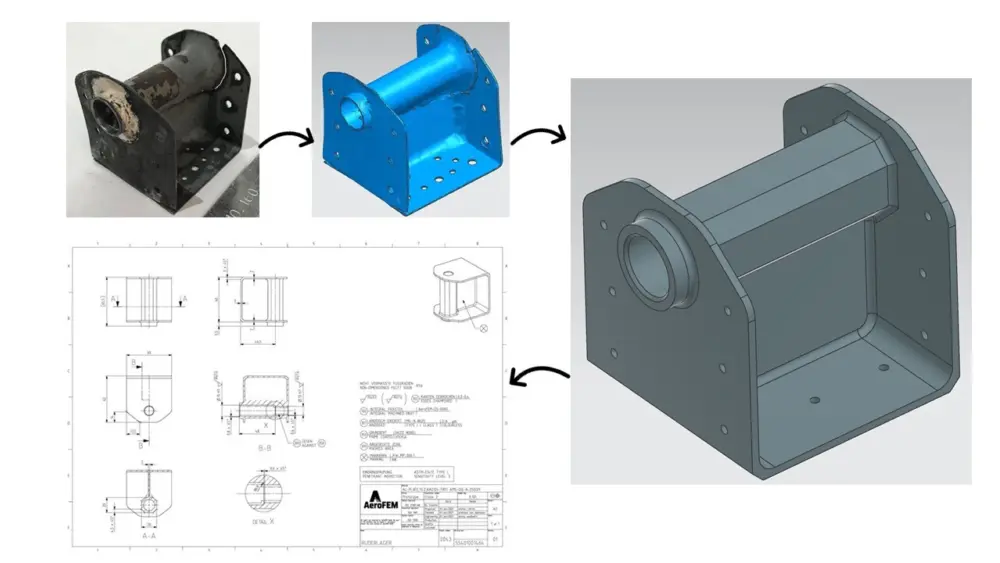

Structural repairs

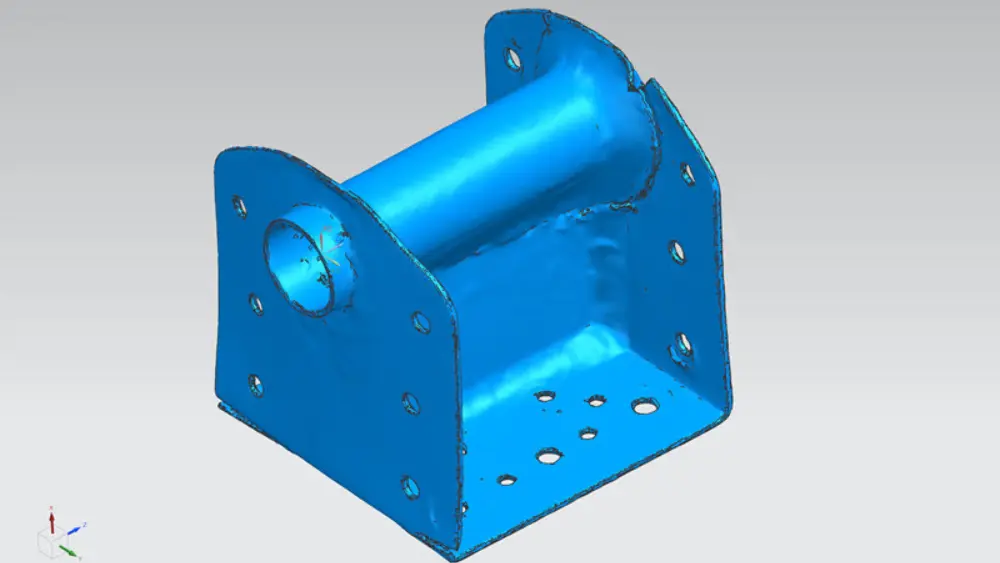

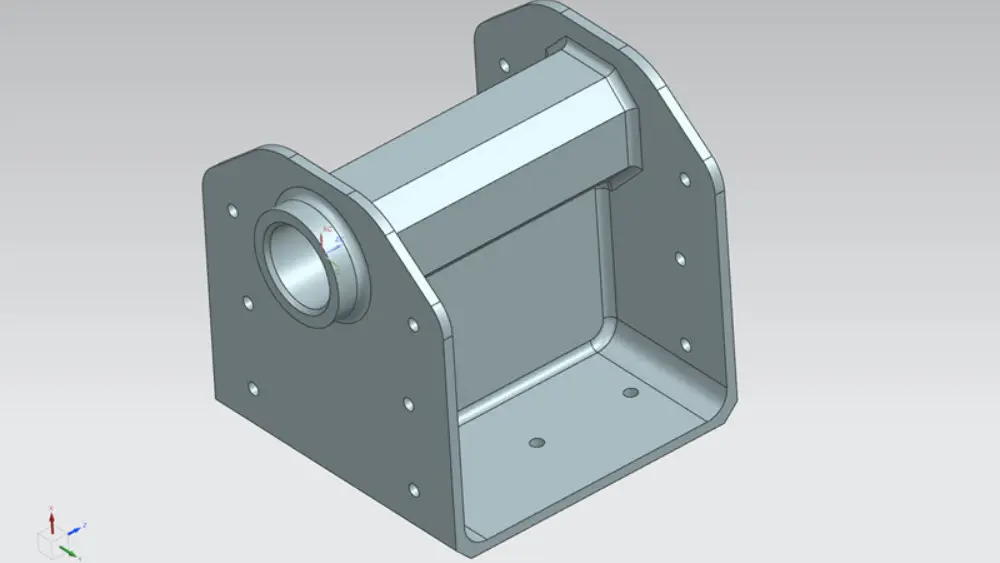

A classic area of application for reverse engineering is repair work. In a past project, AeroFEM was able to offer a customer a comprehensive solution for the repair of a defective bearing. This was necessary because spare parts and production documents were both no longer available.

The bearing in question is an important component with high demands on geometric tolerances. With the data obtained, in a very short time, a complete production drawing could be created according to today's standards and procedures.

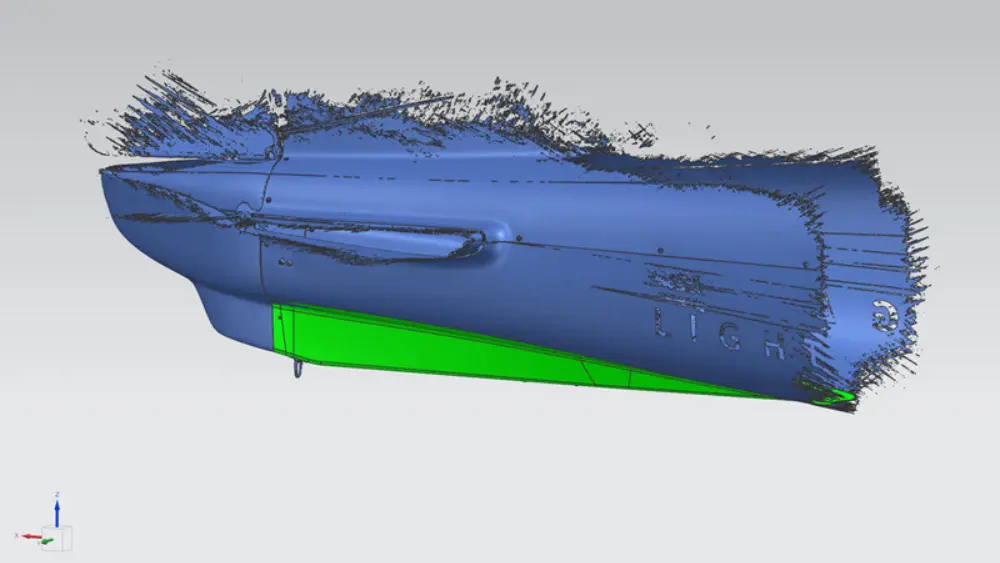

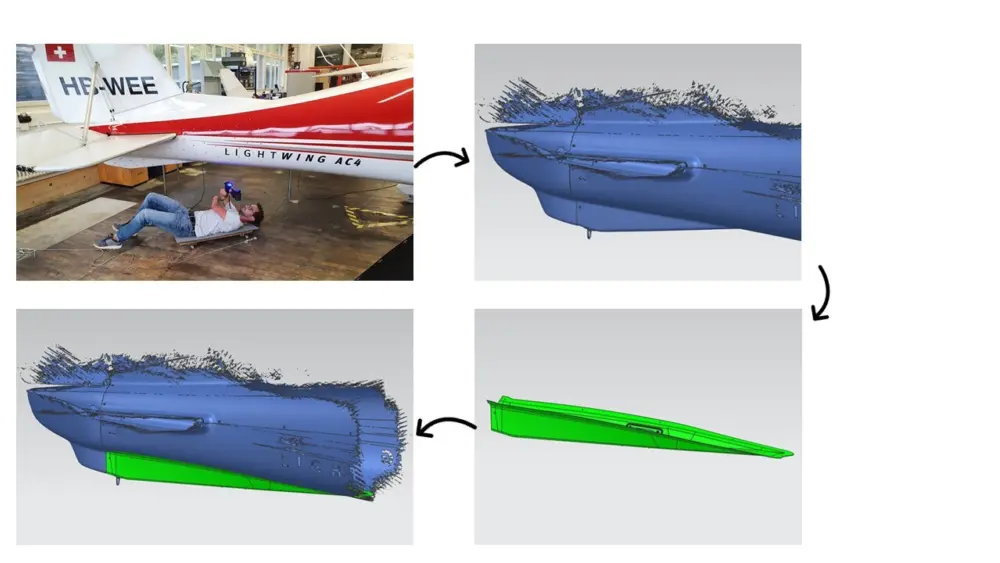

Retrofits

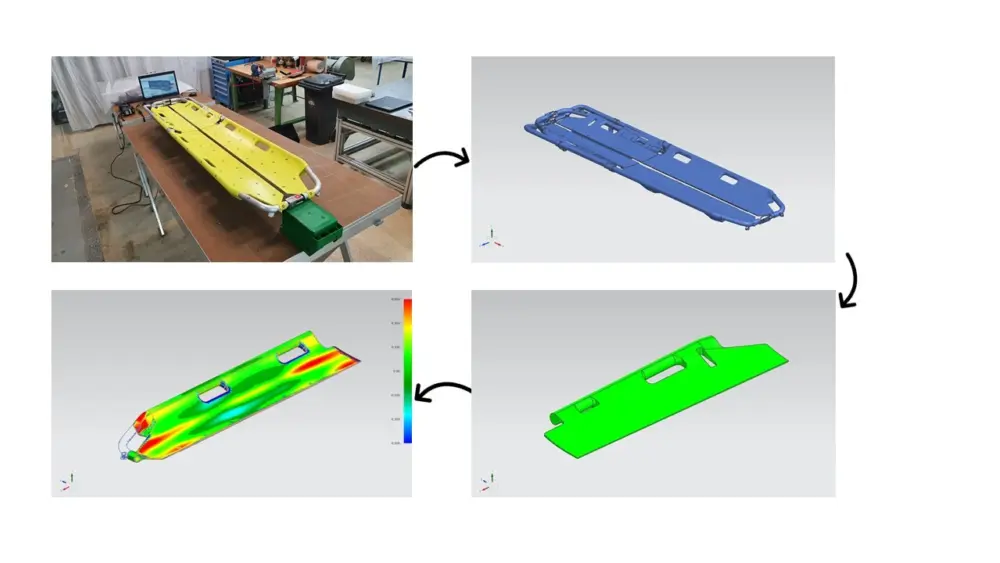

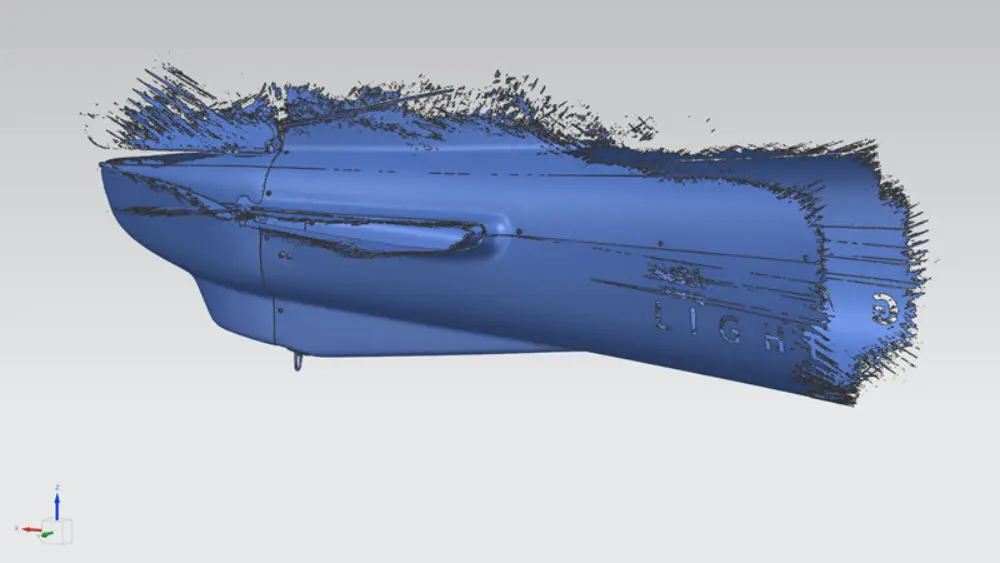

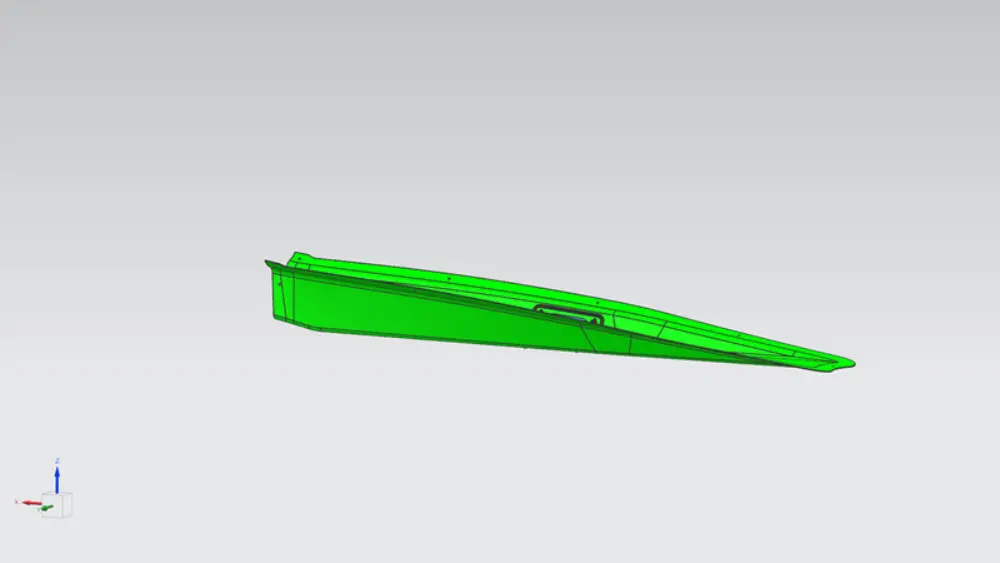

AeroFEM was pleased to support the company LightWing AG with the installation of a towing system for glider aircraft. To make the required adjustments to the composite fairing, this was scanned with a portable 3D scan system. Using the obtained 3D data, a solution tailored to the existing external structure could be developed.

Reverse engineering

The CAD system used by AeroFEM provides an extensive reverse engineering toolbox, which efficiently enables reverse engineering of 3D scan data.

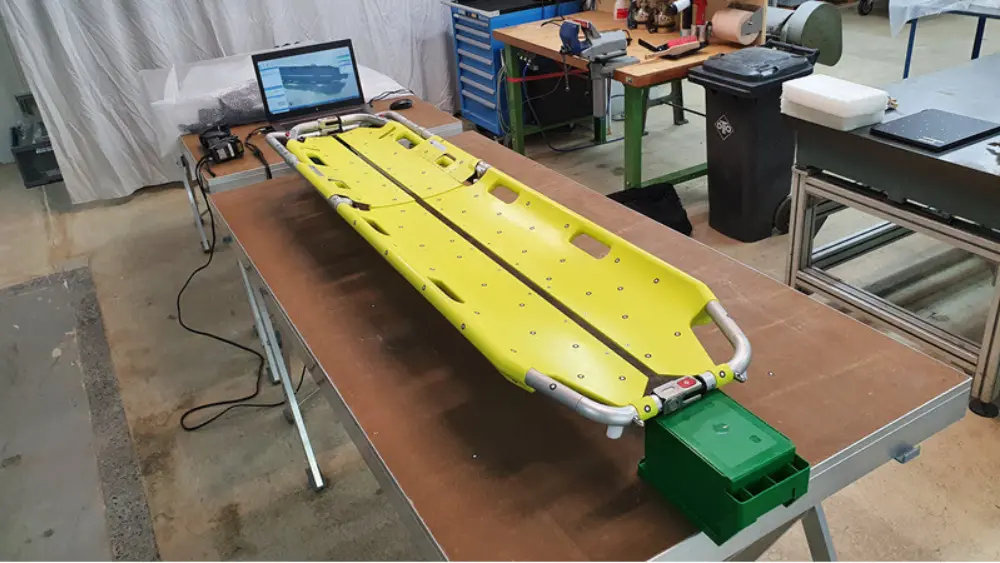

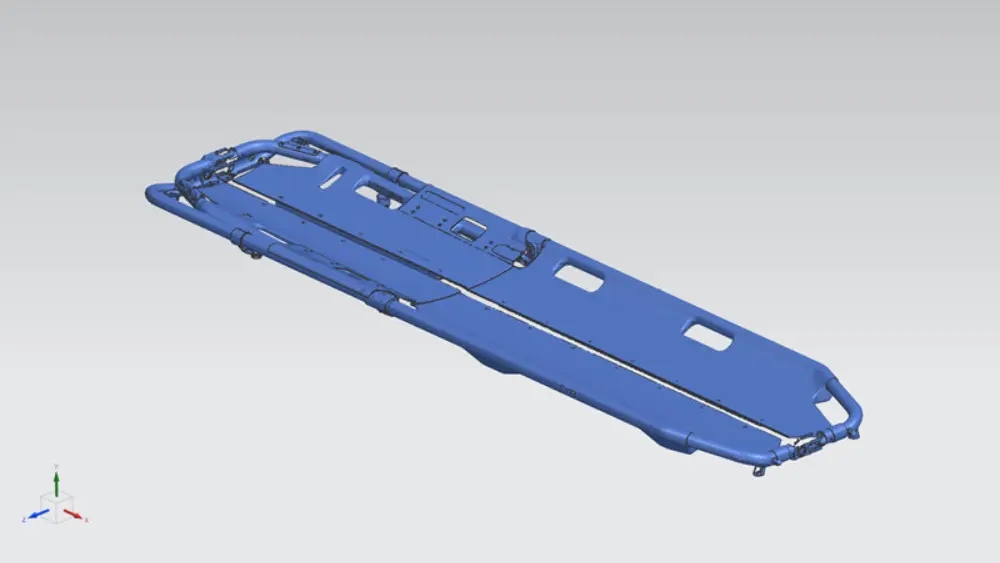

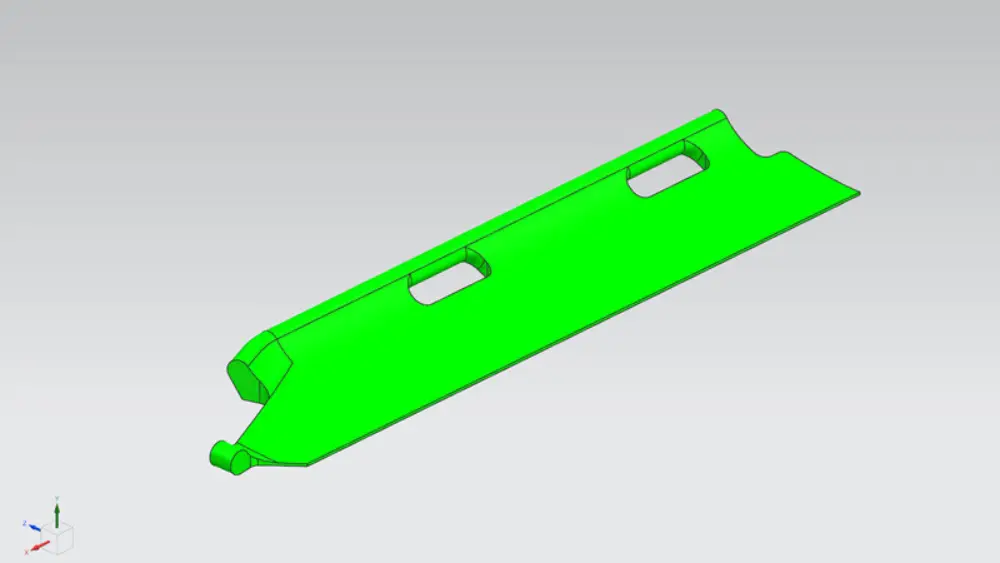

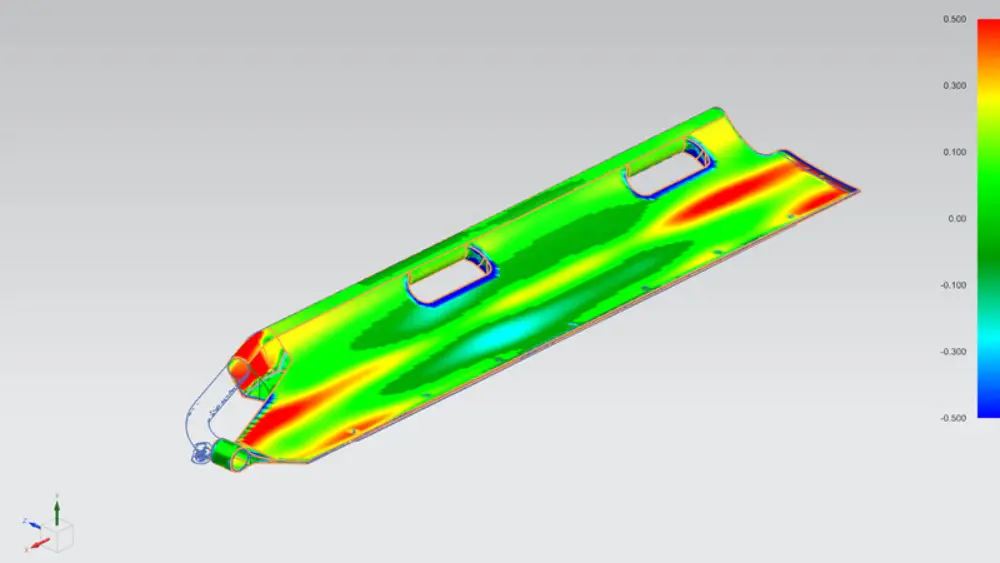

Supporting the company Aerolite AG we were tasked to scan an existing stretcher and convert the data into geometric surfaces. New manufacturing data for the foam cores of the composite structure was created using these surfaces. During the process, care was taken to ensure that the surfaces are regular and show only minor deviations from the original structure. The surface quality and deviation analysis can be carried out and displayed directly in the CAD system.

The quality of the surfaces can be fully adjusted according to customer requirements. Furthermore, the geometry can be created in a parameterised approach, which means that later adjustments and further developments can be efficiently implemented.